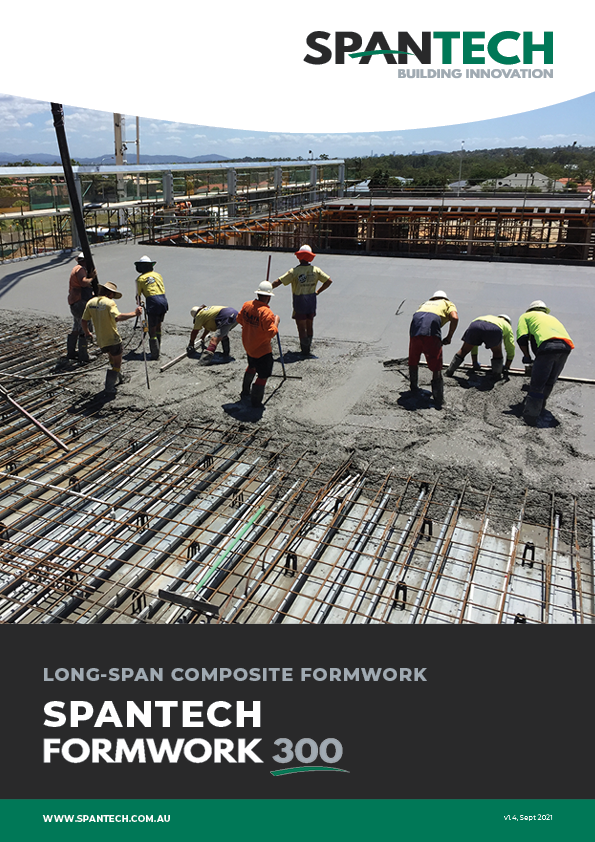

LONG-SPAN COMPOSITE FORMWORK

Spantech FORMWORK 300

Build suspended concrete slabs faster with minimal temporary supports and less reinforcing.

See how Spantech Formwork 300 was used to construct a large, suspended slab for a major Aquatic Centre project.

Key Features

The Spantech Formwork 300 eliminates or significantly reduces the amount and complexity of temporary formwork in suspended concrete slabs to accelerate construction programs and reduce costs.

Very cost effective for multilevel car parks, high rise buildings and other commercial applications

Suit suspended concrete slabs a minimum of 145mm thick. Typical slab thickness is 160mm

Unsupported spans to 3.6 metres (for 160mm slab and live load up to 10KPa). Refer Span Tables

Significant reduction in construction time:

Faster installation

If props are required, there are fewer props

Remove props earlier and faster

Earlier access for all other trades

Integrates with all construction methods:

Structural steel frame

Tilt-up, pre-cast or formed concrete

Masonry walls, etc.

The unique flat base of the profile:

No infill to underside of profile

Minimal flashings

Profiles easily fastened to support structure

Minimal leakage

On-site manufacturing to minimise transport and handling costs, errors and waste

Profile can be pre-cambered (curved) to provide additional strength and minimise deflection

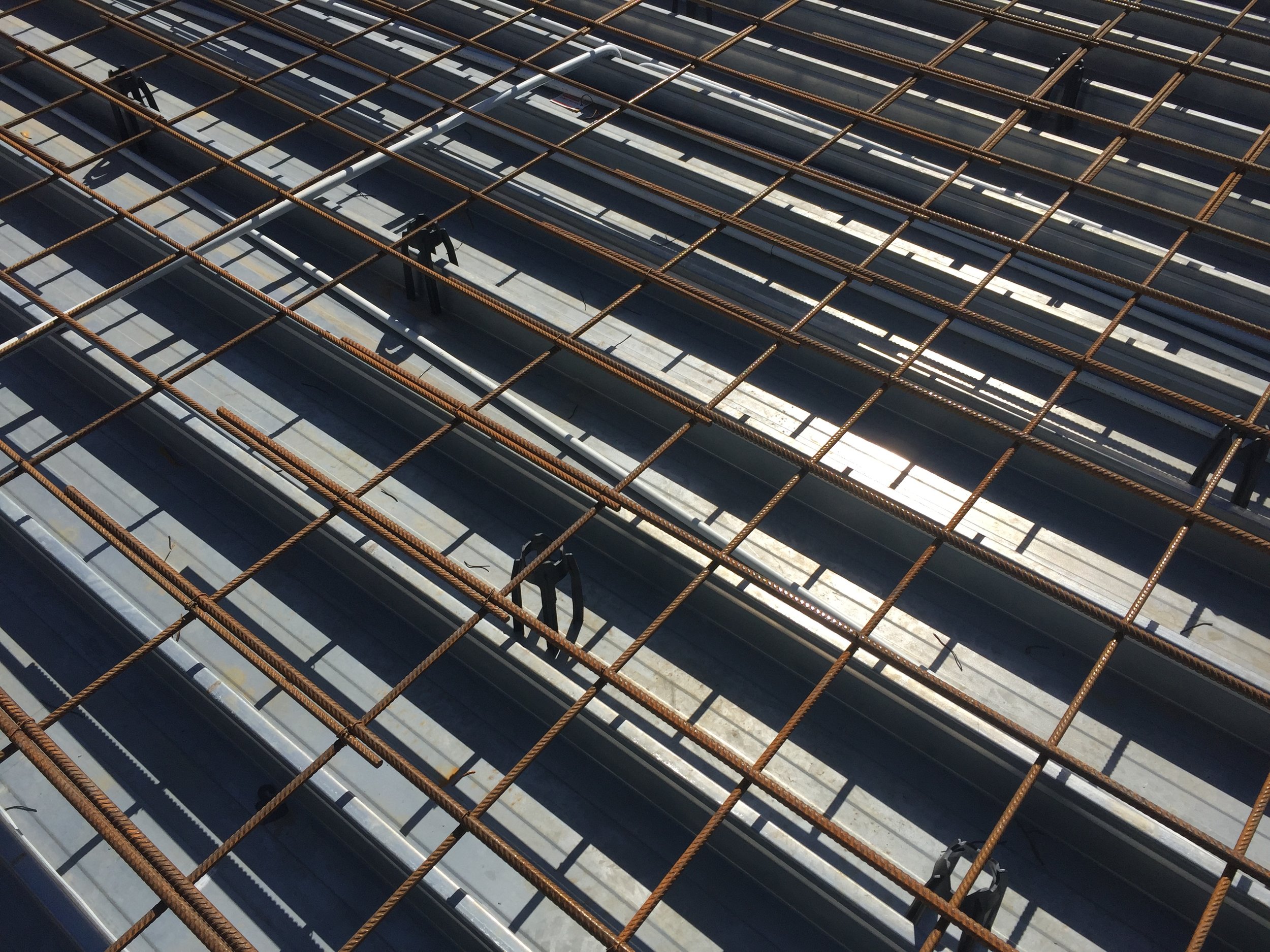

Profiles are connected to each other with a strong patented interlocking connection achieved without fasteners

Bold 110mm (nominal) high ribs act compositely with the finished slab to minimise the quantity of reinforcing required.

The ribs can support reinforcing mesh, eliminating bar chairs

Integrated multi-purpose clips available to support suspended ceilings and services

Excellent Fire Resistance Level (FRL) with 160mm thick slab of 25MPa concrete achieving 240/240/240 FRL. Refer to Fire Design

Acoustic properties meet all relevant standards. Refer to Acoustic Design

Options for coil steel protective coatings:

Galvanised steel

Pre-painted steel - select any colour from the BlueScope range

Printed patterns emulating timber, stone and corten steel from UniCote Lux

* Spans and cantilevers above are for non-cyclone regions, and subject to Engineering design and approval.

< Traditional Timber forms

Spantech metal Formwork 300 >

FORMWORK 300 Profiles

VERSATILE METAL FORMWORK

Formwork 300 is a fast and efficient long-span composite metal formwork system used to quickly form suspended concrete slabs.

It requires minimal temporary supports and less reinforcing to help dramatically reduce construction time and costs.

Specifications

Minimum recommended slab depth: 160 mm*

Maximum span: 3.55 m*

Cover width: 303 mm

Profile depth: 110 mm

Fire resistance level: 240 / 240 / 240*

* Refer to technical brochure for span tables and full engineering details.

THE SPANTECH FORMWORK 300 DIFFERENCE

THE MOST VERSATILE METAL FORMWORK SYSTEM IN NEW ZEALAND.

Spantech Formwork 300 is an innovative composite formwork system which can dramatically reduce the overall construction time and risks associated with constructing suspended reinforced concrete slabs.

Initially developed and tested for several Australian Department of Defence projects, the Formwork 300 system is now widely used for large commercial projects.

Typical applications include:

High rise hotels, residential and commercial buildings

Multilevel car parks

Mezzanine level floors for commercial and industrial projects

Architect designed residential projects, particularly those with sloping sites.

Unlike any other metal formwork, the Formwork 300 profile can be pre-cambered to minimise deflection, or significantly curved to create dramatic free-span arched structures. These arched concrete structures are regularly used in the design of earth-covered buildings*, tunnels, large culverts and blast-resistant buildings.

* Generally, not recommended or cost-effective for residential earth covered buildings.

Projects built with Formwork 300

More Information

The Spantech Formwork 300 product brochure is available to registered architects, engineers and specifiers. Contact us to request a copy.